- Trang chủ

- / Ultron UH114 & UH115 Series

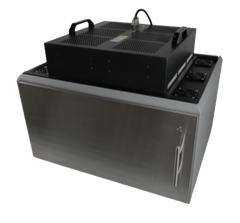

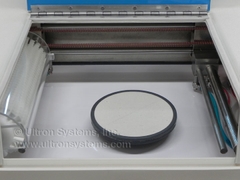

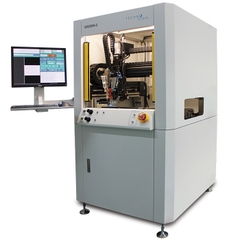

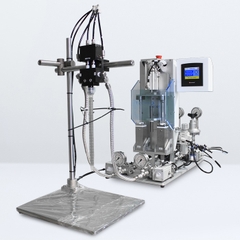

Ultron Systems’ Model UH114 & UH115 Series Mounters set the benchmark for both control and versatility. For dicing/sawing applications, uniform adhesive plastic film lamination is paramount. Our mounters feature an easily adjustable spring-loaded roller assembly, along with film-tensioner bars along both the x- and y-axes to ensure bubble-free lamination of the film to the wafer and film frame. In addition, both models feature a retractable film cutting system with adjustable cutting pressure to accommodate various tape base materials and thicknesses. Roller pressure is adjusted from the topside of the units for different process requirements and to accommodate various wafer thicknesses. A digital temperature controller ensures consistent workstage temperatures for repeatable mounting. Adjustable alignment pins and vacuum cups accommodate almost any type of film frame, including plastic. The workstage height is also adjustable relative to the frame height for different wafer thicknesses. Using our Mounters, operator variables are virtually eliminated.

Our mounters are available in 6″, 8″, and 12″ wafer / film frame models and features:

| FEATURES | UH114 SERIES | UH115 SERIES |

|---|---|---|

| – Easily adjustable spring-loaded roller assembly |

X |

X |

| – Uniform film tension: Film tensioner bars |

X |

X |

| – Automatic motor-driven, one-pass uniform film lamination | X | |

| – Three modes of laminating roller operation: fast, slow, or momentary | X | |

| – Uniform adhesion provides bubble-free lamination |

X |

X |

| – Circular cutter (wheel-type) for cutting film on film frame |

X |

X |

| – Adjustable cutting pressure for different films (thickness/hardness) |

X |

X |

| – Adjustable motorized roller speed and pressure | X | |

| – Digital temperature controlled platen |

X |

X |

| – Adjustable workstage height from top of unit |

X |

X |

| – Operates with non-backed or backed (optional) film |

X |

X |

| – Accommodates film/protective layer wound on the outside or inside |

X |

X |

| – Adjustable alignment pins and vacuum cups |

X |

X |

| – Accepts all film frames (specify type and size) |

X |

X |

| – End cutter for film separation |

X |

X |

| – Accommodates wafers up to 6″ capability (UH114, UH115); wafers up to 8″ capability (UH114-8, UH115-8); wafers up to 12″ capability (UH114-12, UH115-12) |

X |

X |

| – SofTouch (Edge-contact) Workstage | OPTION | |

| – Protective Film Take-up Roller Assembly for use with film with backing layer |

OPTION |

OPTION |