- Trang chủ

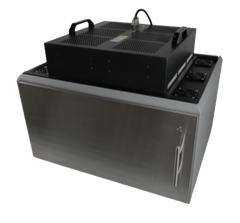

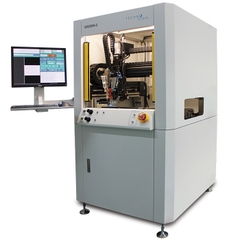

- / Baronete - Automatic Ultrasonic Vapor Degreaser Machine

Technical Specifications

Overall Dimensions : 27” Long x 24” Wide x 42” High

Heat Input : 1,000 watts

Power Supply : 120 VAC-1Ph-60Hz (20A GFCI)

Refrigeration Unit : Air Cooled (¼ HP) R-513A

Refrigeration Heat Load To Room : 3,000 BTU @ 200 CFM

Thermal Capacity Per Hour : 25 Pounds Of Steel/20 Pounds Of Aluminum

Distillation Rate : 1.8 GPH nPB (2.1 GPH Fluorinated Blends)

Total Operational Solvent Fill Amount : 8 Gallons

Allen-Bradley® PLC Control + Color Touchscreen HMI

150 Watt, 40 kHz Ultrasonics+ Digital Sweep Frequency

Generator

Single Axis Programmable Lift + Four User Defined Recipes

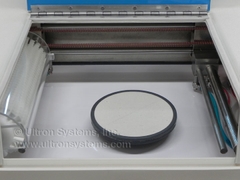

Stainless Steel Work Basket (11”L X 7”W X 3”H, 4X4 Mesh)

Filtration System With Magnetic Drive Pump + 10 Micron Filter

Refrigerated Condensing System (R-513A)

304 Stainless Steel Construction Of All Wetted Surfaces

Stainless Steel Ball Valve Drains

Four Side Tank Insulation + 304 Stainless Steel Skin

Gravity Type Internal Water Separator

Indirect Contact Electric Heater Mounted On Tank Bottom

Standard Features

Sliding Tank Access Cover

All Welding In Accordance With ASME Section IX For TIG Process

Tanks Sections Welded Inside + Out; All Welds Passivated

Solvent Vapor Control

High Temperature Control

Liquid Temperature Control

Low Level Control

User Selectable Control Settings For Multi-Solvent Capability

Audible Cycle Complete Indicator

Structural Frame With Locking Casters

24 VDC Control Voltage

One Year Limited Warranty