- Trang chủ

- / Multi in one servo solution for industrial robots in full load range

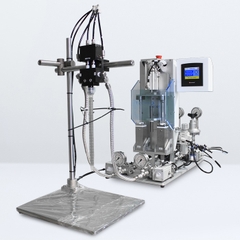

Industrial robots require high operating speed, trajectory accuracy, and repeat positioning accuracy, while also requiring transportation on the belt Maintain the stability of the robot during operation. Industrial robots are very typical multi axis control systems, which enable robots to achieve To achieve high repeat positioning accuracy, in addition to requiring the controller to have a strong path planning algorithm and a small mechanical space for the body Beyond the gap, the servo drive must also ensure fast response and maintain all off state when executing controller position commands Strictly synchronize the sections. In order to improve the running speed of robots, servo systems need to have strong instantaneous overload energy Force, multi axis synchronization performance, and extremely high dynamic response characteristics.

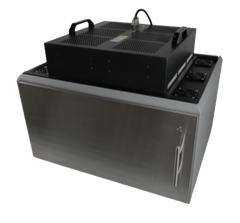

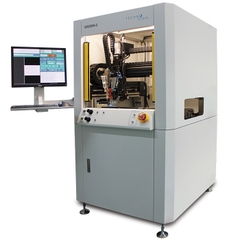

The M820 series modular multi in one bus servo drive is a specialized machine developed by Motong Transmission for the robotics industry Type, integrating multiple new technologies such as common DC bus, integrated motor brake control, dynamic braking, etc., to provide customers with A servo system that is more energy-efficient, flexible, safe, stable, and highly concentrated.

• Standard dynamic braking :Effectively ensure the safe operation of robots

• Reduced commissioning time:Improve work efficiency and reduce application costs

• 3 times overload capacity :Make the robot speed up without worry

• Jitter suppression :?One-click solution to head up and nod; Jitter at boom extension end is eliminated, and track operation is smoother

• Fast response at high speed and stable operation at low speed :Meet the operation requirements of full speed section

For batch industrial robot production, a complete set of parameters are automatically set before leaving the factory and copied with one key, which greatly reduces the debugging cycle and application costs.

• Flexible extension of external additional axis :1~10 shafts, any combination of power (within 4kw)

• Multiple robots can share one electric cabinet

• Covering the full load of 3kg-500kg industrial robot/b>

• Save more than 50% of panel and cabinet working hours