The NovaRay’s microprocessor-controlled system gives operators absolute control over curing parameters, allowing fine-tuned adjustments to match the exact photoinitiation thresholds of different materials. A temperature-stabilized curing chamber minimizes heat buildup, making it ideal for delicate components that require high-intensity UV exposure without compromising material integrity.

What sets the NovaRay apart is its adaptive intensity profiling. Users can create, save, and recall custom curing profiles, ensuring repeatable, consistent results for every batch. Whether it’s adjusting exposure duration or spectral output, the NovaRay removes the guesswork from post-curing, delivering repeatable precision at an industrial scale.

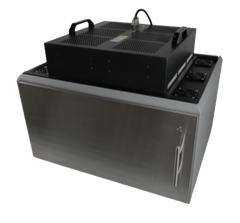

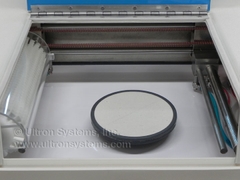

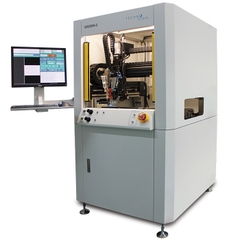

The NovaRay system is a fully integrated UV flood curing solution built for industrial-grade precision and efficiency. At its core, a 600W high-intensity UV arc lamp delivers uniform, high-energy irradiation, ensuring deep, consistent polymerization across a spacious curing chamber. Designed to handle advanced photopolymers, the NovaRay provides optimized curing for 3D-printed resins, industrial coatings, and composite materials, locking in mechanical properties while preventing thermal distortion.

The NovaRay’s microprocessor-controlled system gives operators absolute control over curing parameters, allowing fine-tuned adjustments to match the exact photoinitiation thresholds of different materials. A temperature-stabilized curing chamber minimizes heat buildup, making it ideal for delicate components that require high-intensity UV exposure without compromising material integrity.

What sets the NovaRay apart is its adaptive intensity profiling. Users can create, save, and recall custom curing profiles, ensuring repeatable, consistent results for every batch. Whether it’s adjusting exposure duration or spectral output, the NovaRay removes the guesswork from post-curing, delivering repeatable precision at an industrial scale.

Seamless integration is built into the NovaRay. With USB, Ethernet, and RS-485 connectivity, it fits effortlessly into automated workflows, allowing for real-time process monitoring, automated data logging, and remote diagnostics. Whether used as a standalone curing station or part of a fully networked production line, the NovaRay gives manufacturers total control over their curing process.

Customizable Intensity Profiles: The NovaRay system allows users to create, save, and recall custom intensity profiles, fine-tuning the curing process to meet precise material specifications. This capability ensures consistent, repeatable curing across a range of applications from delicate 3D-printed resins requiring controlled exposure to high-performance composites that demand deeper polymerization. By eliminating trial and error, the NovaRay provides a data-driven approach to curing optimization, enhancing both process efficiency and final material properties.

Advanced Connectivity and Data Logging: Engineered for seamless integration, the NovaRay is equipped with USB, Ethernet, and RS-485 interfaces, enabling real-time process monitoring and remote diagnostics. Its comprehensive data logging system records detailed curing parameters, ensuring full traceability, process validation, and quality control compliance. Whether operating as a standalone unit or within a fully automated production environment, the NovaRay provides unparalleled visibility into curing conditions, helping manufacturers maintain tight process tolerances.

Precision Controls with High-Resolution Touchscreen Interface: The NovaRay features a high-resolution touchscreen interface, powered by an intelligent microprocessor, delivering precise, user-configurable control over exposure time, intensity settings, and spectral output. This level of customization allows operators to optimize UV delivery for each material type, ensuring full polymerization while preventing overexposure.

| System Type: | Fully-Integrated Flood Curing System |

| Part#: | UV4777 |

| Lamp Power: | 600W |

| Input Voltage: | 90–265VAC, wide-range AC line input |

| Input Current (Max @ 120/240V): | 10A max (120V range), 5A max (240V range) |

| Peak Irradiance, Typical at 2.5" (Initial): | 140 mW/cm2 UVA, from bottom face of lamp head |

| Curing Area: | 8 x 6" minimum |

| Weight: | 20.0 lbs |

| Size (L x W x H): | 15.5” x 13.2” x 13.7” |