- Trang chủ

- / Titanium 59%

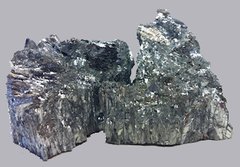

Titanium is a silver-white metal appreciated for its exceptional strength, lightweight nature, and corrosion resistance. These valuable properties have made titanium a sought-after material in various industries, notably aerospace, automotive, medical, and chemical processing. Titanium is available in multiple grades and alloys, each with distinct properties tailored for specific uses. To help you avoid this, this article will act as a titanium guide as it introduces titanium material including describing its properties, discussing titanium and titanium in different grades and applications, and how to select the right grade.

Titanium, a metal with the atomic number 22 and a silvery-white appearance is known for its lightweight, ductile, strong, corrosion-resistant, and biocompatible properties, boasting a high strength-to-weight ratio. This element ranks as the 9th most abundant on Earth, commonly found in rocks, clay, and sand. The primary commercial minerals used for titanium extraction and refinement are rutile and ilmenite. Titanium is categorized into alpha-alloys, beta-alloys, and alpha-beta alloys. Alpha alloys comprise oxygen as the main alloying element and are often combined with metals like aluminum, molybdenum, and vanadium to enhance strength, and corrosion resistance, and reduce weight. Applications of titanium and its alloys span various industries, including commercial and aerospace sectors, power plant condensers, desalination plants, marine environments, architectural structures, medical implants like joint replacements, and consumer products such as golf clubs and bicycle frames.